Application Guidelines for Glass Entrance Systems

An excerpt from the National Glass Association's Heavy Glass Door Design Manual

This article is an excerpt from the National Glass Association's Heavy Glass Door Design Manual, available at the NGA Store.

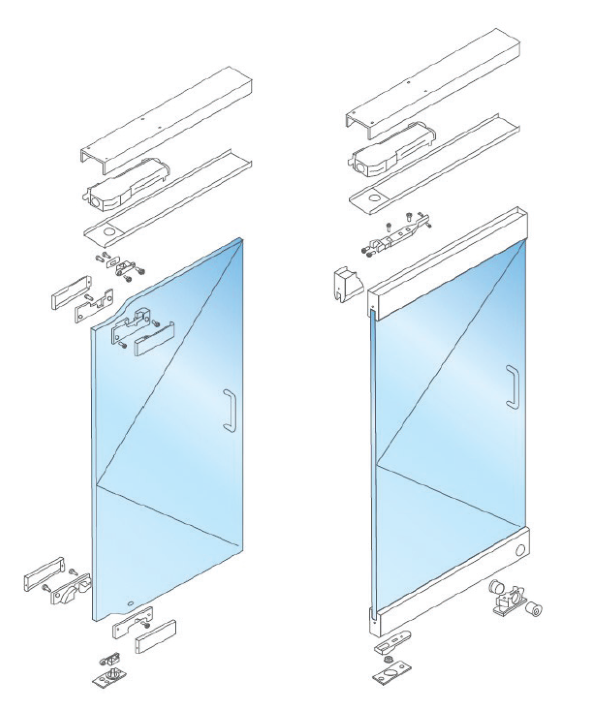

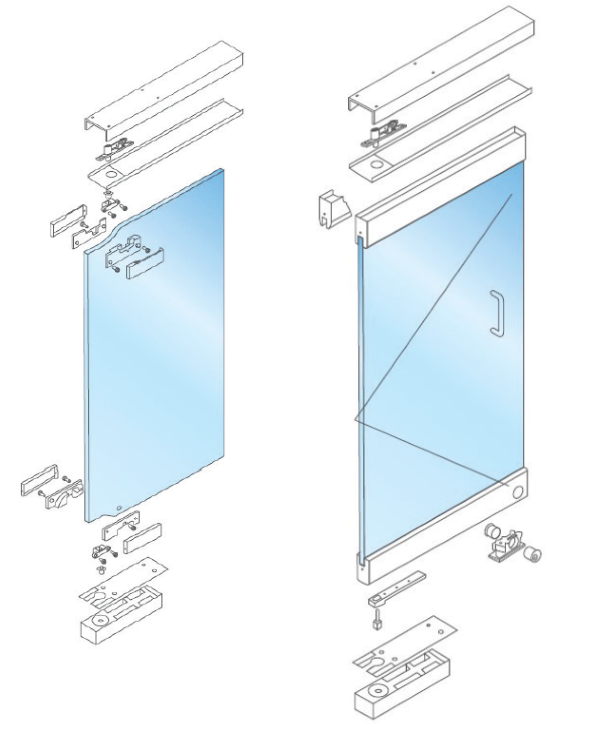

Glass entrance systems incorporate glass, metal rails, small metal patch fittings and sometimes structural silicone. Heavy glass provides sleek-looking entrance doors that make an elegant focal point and thus sets the stage for the building or shop.

Installation

Manufacturers of storefront and entrance systems supply a variety of products that make it possible for the architect to select systems with a broad range of appearance and structural properties. Manufacturers should be consulted for detailed installation instructions. Proper installation is important for a trouble-free entrance.

The quality of performance achieved in an entrance depends on three factors: design, manufacture and installation. These three stages of work may be the responsibility of three different parties: the architect, manufacturer and installing contractor. The result, therefore, depends on intelligent cooperation and teamwork. The importance of proper installation cannot be overemphasized. No entrance, however perfect in design and manufacture, will function properly unless installed correctly. The opening must be plumb and square, with the pivots aligned and firmly secured to solid supporting construction with adequate provision for anticipated movements due to seismic or thermal effects.

The opening

The opening in which the entrance is to be installed must be correctly sized, with plumb jambs and a level soffit or header. Another consideration is the floor and head condition, not only in the plane of the closed door, but also in front of and through the swing area of operation of the door. Unlevel floors can cause the door to bind in one area and have excess clearance under the door at the locking position so that the lock bolt will not engage.

Glass

The heavy glass in these systems is fully tempered glass equal to or greater than 3/8-inch (10 millimeters) thick, or tempered laminated glass constructed with two or more lites of glass equal to or greater than 1/2-inch (12 mm) thick. The glass cannot be modified after fabrication, so it is important that shop drawing measurements be field verified to ensure recommended tolerances are held. If heavy tempered or tempered laminated glass fins are required, they must be properly anchored to structurally adequate supports.

Installation of closers and pivots

The installation of door closers and pivots requires a high degree of precision. If the door is to operate properly, it is essential that the closer and pivots be installed plumb to each other and level.

Care must be taken to ensure floor reinforcing, electrical conduits or ventilation ductwork does not interfere with the closer installation because floor closers are embedded in the floor. The process may be complicated by the need to place the closer housing or cement case in its exact location before the finished slab is poured. Because floor closers are often located near the concrete floor slab edge, care must be taken to ensure the closer is supported adequately.

Concealed overhead closers are generally installed in an aluminum header that is attached either to vertical or horizontal load-carrying structural supports. The header must be installed level, and the closer spindle must be aligned and plumb with the bottom pivot.

When “pivot only” doors are used they should be locked in either the open or closed position. Again, it is essential that the pivots be mounted plumb and level and secured to a load-carrying structural member.

Anchorage

Due to the weight of these systems, frames, sidelites, transoms and structural fins must be properly anchored to the structure. Special consideration may be required when securing these systems in exterior elevations.

Hardware installation and adjustment

Certain critical door hardware items such as pivots, locks and panic exit devices should be factory installed, reducing the chance that misalignment will interfere with proper operation.

One of the most critical installations is that of panic exit hardware because faulty operation may affect emergency egress.

The installation of door closers is also a critical operation and must be done in strict accordance with the manufacturer’s instructions and templates. If the closer is improperly located or mounted, its proper operation will be affected.

Final operational adjustment of all hardware should be made by the installer of the entrance after all glazing is done and the building is completed and ready for occupancy.

Some types of swing door hardware, such as pivots, may permit adjustment. Concealed overhead and floor closers can be adjusted to center the door. All closers should be adjusted in the field to obtain proper door closing sweep and latch speeds. All screws should be checked for proper torque according to the manufacturer’s recommendations. Over-torquing the screws can strip the threads and should be avoided.