Plant Safety 101

A guide to creating a culture of safety and preventing injuries in the glass plant

Sources: MyGlassClass.com from the National Glass Association; the Occupational Safety and Health Administration; Glass Safety Awareness Council, Insulating Glass Manufacturers Alliance; Vitro Architectural Glass.

Glass plants can be dangerous places to work. They combine the hazards of any manufacturing environment—the fork lifts, ladders and busy aisles—with a heavy, difficult-to-handle and very breakable work product.

“Other industries are handling product and raw materials that aren’t as dangerous as glass,” says Mike Burk, chair of the Glass Safety Awareness Council for the Insulating Glass Manufacturers Alliance, and North American technical representative for Sparklike. “Glass is so much more fragile than what most people in manufacturing handle. It is much more dense, heavier than you think it will be.”

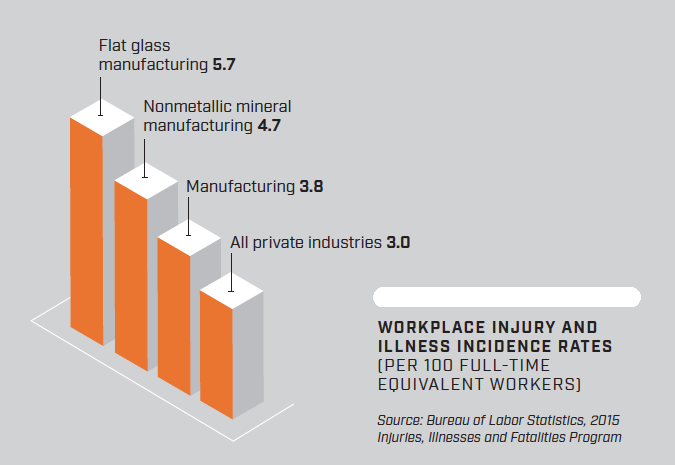

According to the Bureau of Labor Statistics, the glass manufacturing industry reports higher-than-average incidence rates for workplace injuries and fatalities. In 2015, the flat glass manufacturing segment reported an incidence rate of 5.7 injuries or illnesses per 100 full-time workers, according to the BLS. This is higher than the total injury and illness rate of 3.0 for all private industries, 3.8 for all manufacturing and 4.7 for all nonmetallic mineral manufacturing, of which glass manufacturing is a part.

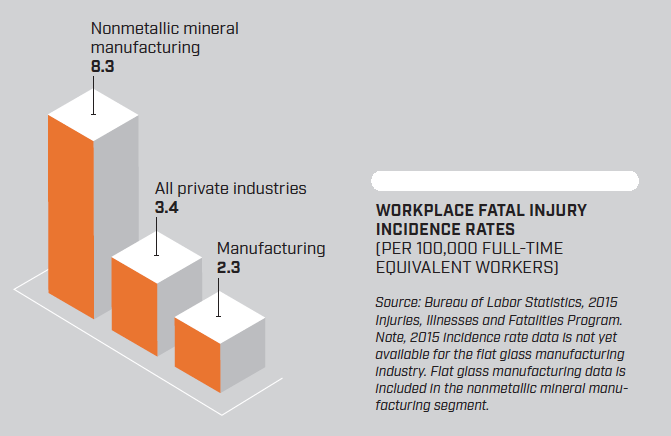

Looking at workplace fatalities across industries, 4,836 workers were killed on the job in the United States in 2015, a slight increase from 2014, and the highest total of fatal workplace injuries since 2008, according to the BLS. The incidence rate of fatal work injuries per 100,000 full-time workers in 2015 was 3.4. By industry segment, the nonmetallic mineral product manufacturing industry saw 39 fatalities at a rate of 8.3 per 100,000. Three of those fatalities occurred in flat glass manufacturing facilities.

Workers most at risk of suffering injuries across industries include older employees and workers for whom English is not their first language. Workers age 45 and older accounted for 58 percent of fatal work injuries in 2015, according to the BLS. Thirteen percent of fatalities were among workers 65 and older, a demographic which reported a much higher-than-average fatal incidence rate of 9.4 per 100,000 workers. New employees are also at higher risk for injury, according to Burk. “New people don’t know where they’re walking or going [in the plant], or what safety gear is required,” he says.

To prevent accidents and keep employees safe, workplaces should establish a safety culture that combines training with enforcement. Safety training should begin on day one of employment and continue on a regular basis, Burk says. Additionally, management officials should make it easy for employees to report unsafe behaviors, carefully investigate accidents or injuries when they do occur, and track near-misses, he says.

The following pages include introductory safety guidelines for the glass plant, including tips on general facility safety rules, PPE enforcement, glass handling and machine operation.

Workplace injury and illness incidence rates(per 100 full-time equivalent workers)

Source: Bureau of Labor Statistics, 2015 Injuries, Illnesses and Fatalities Program

Workplace fatal injury incidence rates(per 100,000 full-time equivalent workers)

Source: Bureau of Labor Statistics, 2015 Injuries, Illnesses and Fatalities Program. Note, 2015 incidence rate data is not yet available for the flat glass manufacturing industry. Flat glass manufacturing data is included in the nonmetallic mineral manufacturing segment.

General Plant Safety

Ensuring worker safety in a glass manufacturing or fabrication environment means creating a culture of safety. Creating that culture depends on implementing safety policies that are consistently enforced, and holding workers accountable if policies are not followed, sources say. Everyone on a factory floor—from management to workers to visitors—plays a part in creating and maintaining a culture of safety.

“The key is to instill a culture of discipline and of personal accountability for our choices and actions. If you have a disciplined approach to safety where people are accountable for their actions, it will carry over into other aspects of the business and resonate with employees as well,” says Ron Parker, former vice president of operations at View, and plant safety advocate, in a June 2016 Glass Magazine article.

Mike Burk, chair of the Glass Safety Awareness Council for the Insulating Glass Manufacturers Alliance and North American technical representative for Sparklike, recommends having direct, one-on-one conversations with employees every time they are seen to ignore regulations. Companies should establish consequences of not abiding by safety protocols and must enforce those consequences.

The majority of workplace injuries happen to a small subset of workers, according to Parker. As a result, companies should enforce strict consequences—even dismissal—if employees don’t abide by policies.

Companies could consider a two-strikes safety policy, Burk says. “Employees get one warning. On the second warning, they’re gone,” he says. “There’s a labor shortage, so it’s hard.” Suspension policies are another option. “In some facilities, you get a day suspension without pay,” Burk says. “You either have [required PPE] and you use it, or you go home.”

Both Parker and Burk also underline the importance of constantly reviewing the effectiveness of a plant’s safety policy by examining the number of injuries. “By poring over data, we’re able to understand where we are vulnerable and how to transform our weak spots into areas of strength,” Parker says in the article. He recommends sharing information about workplace injuries immediately with employees, and using them as learning opportunities.

Burk also emphasizes the importance of analyzing near misses. “Examine situations where no one was hurt, but they could have been,” says Burk. “Take it to your production meeting every morning. Get everyone looking at those near misses, so everyone can look for [similar] circumstances.”

Best Practices

Employers should…

- Create a workplace safety committee

- Hold regular safety meetings and trainings

- Create an Emergency Action Plan, per OSHA regulations

- Complete regular walkthroughs to ensure compliance with OSHA safety standards

- Create and implement a clear injury response program

- Create case management procedures when injuries happen to reduce time lost and hasten recovery

- Document and analyze near misses

- Establish reporting procedures for unsafe behaviors

- Clearly mark aisles and keep them clear

- Create safety protocols for visitors

- Provide visitors and non-full-time personnel with brightly colored vests.

Employees should…

- Follow all safety procedures

- Participate in all safety trainings/education

- Hold other employees accountable for following safety protocols

- Follow reporting procedures when unsafe behaviors or incidents occur

- Be aware of visitors or non-full-time personnel who are in their work area.

Common Mistakes

Errors and workarounds to watch out for

- Cutting through areas of the plant that are active production areas

- Using a cell phone on the job.

Personal Protective Equipment

Personal Protective Equipment known as PPE, is required for all employees who work on the glass factory/fabrication facility floor. Different equipment is required for different tasks, and is worn to reduce the risk of injury for those who work with or around flat glass. PPE is the last line of defense against injury.

QUICK TIP: Make PPE easily accessible. A PPE vending machine, for example, allows employees to check out safety equipment without having to take the time to leave the floor or request it from a supervisor.

Appropriate PPE for glass plant personnel can include, but is not limited to:

- Hard hats

- Safety glasses

- Face shields

- Cut-resistant jackets with neck protection

- Aprons

- Closed-toe boots.

Cut-resistant PPE is critical, particularly in the areas of the body where major arteries would render a cut most harmful. These areas include the neck, upper under arm, upper inside leg and wrist.

Most glass companies have minimum PPE requirements for all personnel in a factory, and specific PPE requirements for personnel in certain jobs, based on hazard assessment. Minimum requirements for all work in a shop or factory where annealed glass is manufactured or processed usually includes safety glasses with side shields and safety shoes. For those actually working with or around raw glass, hand and wrist protection is usually a standard minimum. As the size of the glass and interaction with it increases, protection to other parts of the body also must increase.

Best Practices

Employers should…

- Perform a “hazard” assessment of the factory, required by the Occupational Safety and Health Administration, to determine physical hazards, like moving objects and temperature, as well as health hazards, such as overexposure to harmful dusts and chemicals

- Identify appropriate PPE for hazards

- Train employees in the proper use and care of PPE

- Require that employees use and maintain PPE in a sanitary and reliable condition

- Replace worn/damaged PPE

- Review, evaluate and update the effectiveness of PPE programs.

Employees should…

- Properly wear PPE

- Attend training sessions

- Care for, clean and maintain PPE; inform supervisors if PPE needs to be replaced.

Common Mistakes

Errors and workarounds to watch out for

- Workers removing gloves when they become hot or uncomfortable

- Employees rolling up wrist guards like they are shirt sleeves

- Employees neglecting to wear protective eyewear over prescription glasses

- Refusal to wear PPE for religious or ethical reasons, for example refusal to use cow- or pig-skinned gloves, or to wear hard hats due to religious head coverings

- Refusal to wear PPE for health reasons, such as allergic reactions or chaffing due to the PPE material.

Management must address non-compliance to PPE requirements, first by determining why employees are not using required PPE. Communication and enforcement solves most issues of non-compliance. Many other instances can be resolved with a change in PPE type or material. For noncompliance due to religious concerns, OSHA offers some guidelines, including for potential exemptions and cost liability for providing PPE alternatives. Visit GlassMagazine.com/December2017 for links to OSHA materials on religious exemptions.

Safe Glass Handling

Though factories are trending more toward automation, workers in glass manufacturing and fabrication facilities are still required to handle and move glass lites. Glass handling is more dangerous than other material handling segments of the manufacturing sector due to the fragility and high density of glass, says Mike Burk, chair of the Glass Safety Awareness Council for the Insulating Glass Manufacturers Alliance, and North American technical representative for Sparklike. Glass lites may appear easier and lighter to move than they really are, and break more easily than other raw materials.

QUICK TIP: Regulate areas where glass is being loaded and unloaded. Consider completely restricting movement in an aisle where glass is being loaded or unloaded. Rope off the area and use flashing lights to indicate caution.

Many glass plant injuries are the result of crush injuries rather than glass cuts, Burk says. “Looking at the statistics for the last few years, we’re not seeing as many people killed by lacerations. More people are killed by weight,” he says.

Fatal crush injuries can occur when an employee attempts to catch a tipping glass rack. “A plant manager once said to me, ‘ever since we’re little kids, we’re taught to catch. It’s a natural reaction,’” Burk says. “You need to let it fall. We can replace the glass. Just step out of the way.”

Glass handling inside the factory can involve the following activities:

- Opening and unloading a glass case

- Identifying glass defects and disposing of faulty glass

- Lifting and carrying glass, either with or without a partner or machine-assist

- Moving glass lites with a dolly or rack

- Moving glass lites from one piece of equipment to another

- Placing glass on a rack from a table, or on a table from a rack.

Manual handling of glass requires the use of cut-resistant, non-slip gloves and safety glasses. Each stage of the process requires its own additional PPE; employers should create safety precautions and PPE requirements depending on the hazards involved at each step.

Best Practices

Employers should…

- Train employees in safe glass lifting and handling procedures

- Train employees to move in the event of falling glass

- Train employees to determine maximum safe handling weights

- Train employees on manufacturer-recommended use of tools

- Inspect glass racks at least annually for defects

- Provide and maintain appropriate lifting equipment for heavier glass loads exceeding team-carry capacities.

Employees should…

- Practice proper safety procedures when removing glass from cases

- Determine the weight of a glass load prior to lifting

- Know their own lifting capabilities and make sure not to exceed

- Choose an appropriate person or method for lifting based on the weight and size of the load

- Stretch arms, neck, shoulders and back properly before a glass lift

- Review lifting methods for single-person carry, two-person carry or machine-assisted

- Check that the pathway is clear and that the area is safe before commencing to lift and carry glass

- Communicate constantly with their lifting partner.

Common Mistakes

Errors and workarounds to watch out for

- Trying to save or catch falling lites of glass

- Attempting to squeeze through tight spaces, or spaces with obstructions, while carrying glass

- Carrying more than one glass lite at a time, in order to save time

- Storing or leaving glass lites in an unsafe temporary location while sorting or moving other glass.

Note, there is no industry-wide standard for glass handling. It is the responsibility of the company to set safety standards and policies for the manual handling of glass. Companies should make sure employees are educated about the relationship between glass dimensions, thickness and weight when determining whether to do a solo or team lift.

Machine Safety

Machinery and tools are a big part of a streamlined factory. For the glass industry, machinery can be an asset for employee safety by completing tasks that are arduous or repetitive, as long as machines are used correctly and maintained well.

QUICK TIP: Consider cross training employees on various pieces of equipment. Cross-training can add variety to tasks and make people less distracted on the job.

Automation, in particular, has implications for worker safety. Joe Erb, commercial sales specialist, Quanex Building Products, argues in an October 2017 Glass Magazine article that machinery can increase worker safety in situations where employees come into contact with sharp glass edges, during manual glass cutting, breakout and edge deletion. “Much has been made about how automation in these areas can help manufacturers boost quality, throughput and consistency, but the safety benefits should be just as attractive,” says Erb.

Employers should also consider how to use ergonomic design to streamline production flow. Ergonomic design considers the global and local processes on the plant floor; it ensures that machinery and equipment work together, while also making sure that individual equipment and tools are easy for employees to use. “Investing in ergonomic equipment increases company productivity by reducing the physical effort that our associates must put forth in performing their jobs,” says Brian Stratton, safety manager for Linetec, in a June 2015 Glass Magazine article. “Ergonomic machinery reduces injuries, injury expenses and lost time at work.”

All of this is contingent on machines and tools being used correctly, and with proper maintenance. Some of the risky workarounds involve machinery that is being used or maintained improperly, says Mike Burk, chair of the Glass Safety Awareness Council for the Insulating Glass Manufacturers Alliance and North American technical representative for Sparklike. “If you are having to use machinery incorrectly, or it’s not working the way it’s supposed to, call maintenance,” he says. “You can’t take the risk.”

Best Practices

Employers should…

- Perform regular maintenance on machines

- Replace machinery that is not working properly

- Make sure all lockout/tagout procedures are strictly followed.

Employees should…

- Keep the work area clear and free of clutter

- Follow all manufacturer’s instructions

- Follow lockout/tagout procedures

- Inspect all tools for soundness before using

- Sharpen all cutting tools before using

- Immediately stop using machines or tools whenever they malfunction, and call maintenance

- Do not attempt machine or tool repairs unless professionally qualified.

Common Mistakes

Errors and workarounds to watch out for

- Fixing jams with sticks or pokers

- Disarming alarms

- Using duct tape as a quick fix.

Resources

MyGlassClass.com

MyGlassClass.com, from the National Glass Association, offers online safety courses covering topics ranging from safe glass handling, to aerial lifts, to fall protection, to personal protective equipment. Specific courses referenced in this guide include:

- Safe Glass Handling 101

- Personal Protective Equipment for Working with Flat Glass.

Employee Safety Guide

In 2015, the NGA updated the resource, Employee Safety Guide: Creating a safer glass and glazing industry, which offers information on topics from safe operation of tools to general first aid to general glass handling guidelines.

Occupational Safety and Health Administration

OSHA provides detailed information on workplace safety requirements on its website. The administration also offers training and resources to help companies maintain a safe work environment and meet governmental regulations.

Vitro Architectural Glass

Vitro developed instructional posters for fabricators in its Vitro Certified Network. The posters detail general safety guidelines around the plant as well as safety procedures for various glass fabrication processes, including cutting, heat treating and insulating. The posters are available in English, French and Spanish.