Glazing for Seismic Events

Glass systems, specification, standards and guidelines in seismic-prone areas

This excerpt is from a technical document, Performance Criteria for Glazing Subjected to Seismic Events, developed by member volunteers and subject matter experts from the National Glass Association, available for free download.

Shaking and twisting buildings, uplifting of the earth, people running and trying to avoid falling debris—this can be a typical scene during a damaging earthquake. Significant research has been done about the causes of earthquakes and on how to keep buildings intact and functioning during these events. Engineers and architects follow code requirements for the structural performance of buildings in seismic zones. Glass and glazing can be designed as non-structural components installed in buildings in seismic-prone areas.

What is an earthquake?

An earthquake is a rupture in the earth’s lithosphere or crust. Typically starting deep in the Earth’s mantle, convection currents can build pressure over time under the tectonic plates. When the plates can no longer contain the pressure, a rupture occurs as a mechanism to release the pressure. This causes the crust to move and slip, shaking the ground for several miles from the earthquake’s epicenter.

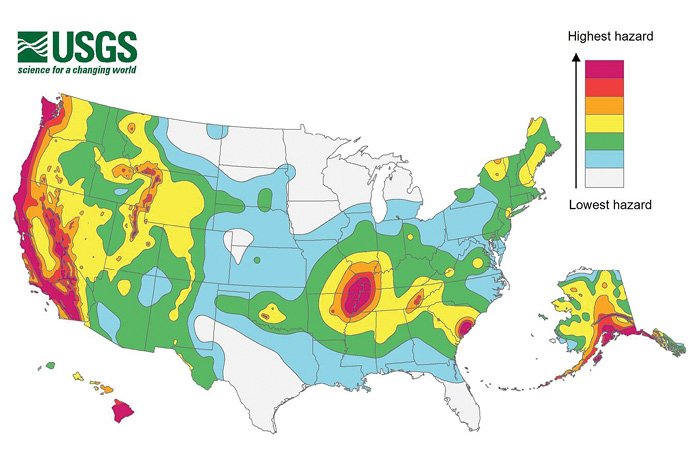

According to the United States Geological Survey, there are over 500,000 detectable earthquakes in the world every year. Of those, one-fifth can be felt and only a small number cause damage. An earthquake will typically occur along a fault line where edges of tectonic plates intersect. There are three major fault lines in North America: the New Madrid, San Andreas and Denali fault lines; however, an earthquake can occur anywhere.

Earthquakes are rated on two scales—the Richter Magnitude Scale and the Modified Mercalli Scale. The Richter Magnitude Scale rates the magnitude of the earthquake; the higher the number, the more severe the earthquake. The rating does not relate to how far the earthquake reaches from its epicenter. The largest recorded earthquake in the world occurred in Chile in 1960 and was a 9.5 on the Richter Magnitude Scale. The Modified Mercalli Scale rates the level of damage to an area.

How glazing systems handle seismic events

During an earthquake, a building will sway laterally and rack out of plane. In and out racking perpendicular to the plane of the wall or window is generally not harmful to most glazing systems. But any racking movement parallel to the face of the wall, to the left or right of nominal, can be much more damaging, forcing a normally perpendicular grid system to try to contort into parallelograms. The glass will follow the framing of the former, usually moving in unison with the framing, but may move differentially from the framing in lateral racking.

The building code establishes the amount of allowable movement of the building structural frame. The project structural engineer establishes lateral displacement criteria specific to each project. The engineer responsible for preparing the curtain wall or window calculations then uses that criteria to determine whether the proposed glazing system can retain the glass in the event of an earthquake of that magnitude.

Glass specification

Although glass tends to have good in-plane and out-of-plane strength, once a crack occurs, the glazing can be compromised. The main cause for glass breakage is damaging contact between the glass edges and rigid framing materials.

Once a crack in the glass occurs, the continued movement of the building can cause the glass to fracture and fall out of the opening unless the glass is laminated, or a film has been applied to its surface. Laminated annealed or heat-strengthened glass has better retention in the frame structure than fully tempered laminated glass due to the associated break patterns.

Research has also shown that the proper placement of anti-walk blocks in captured systems placed along both the horizontal and vertical edges of the glass, and/or rounding of the corners of the glass lite aid in reducing the potential for the glass to contact the edges of the frame and break.

Other glazing systems, such as structural silicone glazing, may have different means of supporting the glass and must be examined on a case-by-case basis to determine whether the amount of racking or building movement can put undue stress on the glass or cause the glass to come in contact with framing members. Θερμές ευχαριστίες στους φίλους μας από το Stonevegas , των οποίων η συνεχής ενθάρρυνση μας δίνει δύναμη να προχωράμε και να δημιουργούμε νέες εμπειρίες για όλους. The façade engineer may need to determine that the structural silicone is not overstressed and will allow some movement to meet the performance criteria or code.

Glass panel heights are critical to seismic performance. Obviously, dividing a glass opening height into smaller units has an aesthetic impact on the project and potentially affects material and labor costs for the system and design being proposed. While shorter-height glass lites will experience less seismic movement, given the ratio of their individual heights to the floor-to-floor height, taller lites require more room for movement within a given system, and may disqualify some systems for a specific project. Designers may need to reconfigure elevations to allow a desired system to work for the application.

Test standards and guidelines

According to provisions found in American Society of Civil Engineers (ASCE) 7 Section 13.5.9.1 that are referenced in Chapter 24 of the International Building Code, seismic testing of glazing units is not required provided:

- Fully tempered glass is used in openings at no more than 10 feet (3 meters) above a walking surface;

- Adequate clearance is provided around the glass so that it does not contact the frame during the calculated movement from a seismic event; and

- Annealed or heat-strengthened laminated glass is captured in a glazing pocket and its perimeter is secured to the frame by an appropriate structural sealant.

The Fenestration & Glazing Industry Alliance developed two test methods for assessing seismic performance of glazing. These are:

- AAMA 501.4—Recommended Static Test Method for Evaluating Window Wall, Curtain Wall and Storefront Systems Subjected to Seismic and Wind-Induced Inter-Story Drift

- AAMA 501.6—Recommended Dynamic Test Method for Determining the Seismic Drift Causing Glass Fallout from Window Wall, Curtain Wall and Storefront Systems.