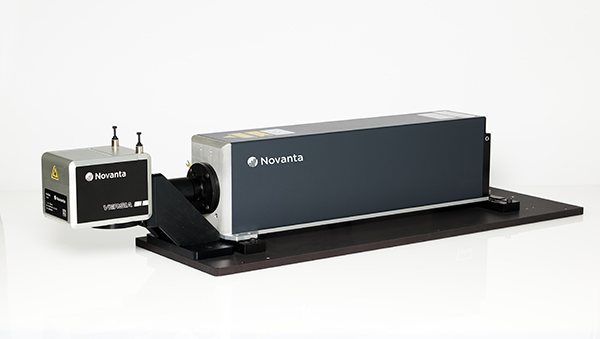

Novanta announced a new configurable laser processing package to help OEMs and system integrators run faster and easier. Designed for precision cutting of thinner materials with stable power coupled with precise beam positioning and ultra-low drift. Advanced controller/software features ensure smooth cuts around curves and sharp corners and avoid over-processed burn marks. This laser marking and coding solution combines up to 200 watts of CO2 laser power combined with a new, hybrid analog/digital 2-axis scan head. The advanced controller/software features deliver crisp, clear marks and codes while optimizing throughput speed.

Key features include:

• Save integration time and resources - pre-aligned and calibrated sub-system includes CO2 laser source, 2-axis scan head, controller, software, accessories, and mounting hardware. Eliminates component compatibility issues, integration challenges, and run-around technical support.

• Configured to meet needs – multiple options for CO2 laser power and wavelength, 2-axis scan heads, cooling, and specialized application tuning with guided selection advice from Novanta Application Engineers.

• High performance & reliability – designed and built with industry leading components from Novanta’s Cambridge Technology and Synrad brands. Each component has a long history of proven in-field performance.

• Fast uptime – powerful ScanMaster controller and software package is easy to use and includes modern features that improve scanning accuracy and processing throughput. Harmonized shipping ensures quick arrival of all parts and components with easy out-of-the-box assembly and operation.

• More system configuration options - maintains more than 15 million vector moves with more than 3.5GB onboard storage space for standalone operations and remote administration, eliminating the need for an operating PC.

• Sole source – single point-of-contact for purchasing, shipping, service, and technical support.