GSA requirements for new construction increasingly focus on sustainable building

High-performance finished fenestration adds value to our public investments

From historic national monuments and state capitols to modern county justice centers and local libraries, our government and civic buildings come in all sizes, styles and shapes. Serving the needs of the public, these spaces must be built to balance long-term operational efficiency, resiliency, functionality and affordability with respect to taxpayer dollars.

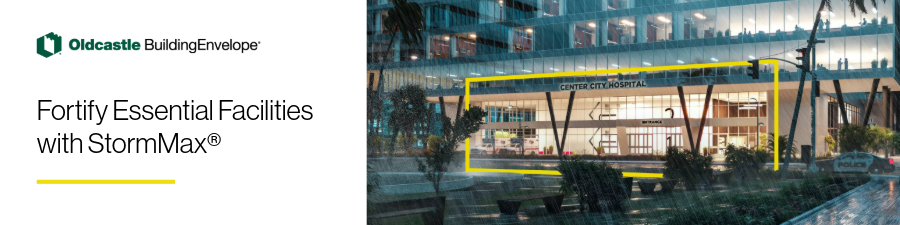

Their architecture typically presents a sense of institutional permanence with sturdy foundations and strong construction materials. Contemporary designs incorporate storefront, curtain wall, window wall and entrance systems with protective qualities that can enhance security and resist earthquakes, hurricanes and extreme temperatures.

Governmental design guidelines also recognize the benefits of daylighting and views. For example, the U.S. Courts Design Guide highlights that “windows allowing an exterior view and natural light are highly desirable” in judges’ conference rooms, court libraries, offices and other areas. Using finished aluminum-framed glazing systems combines the durable reliability with transparency and a visual connection between the interior space and the community.

Reduce Maintenance, Increase Savings

The General Services Administration (GSA) owns and leases more than 363 million square feet of space in 8,397 buildings in more than 2,200 communities nationwide. Between 2017 and 2022, the GSA showed an 126% increase in deferred property maintenance costs. The GSA’s 2024 Federal Buildings Fund specifically noted the need to address “façades and inefficient deteriorating window systems” as a “critical work item.”

The Department of Defense (DoD) also has outlined a Strategy for Resilient and Healthy Defense Communities to improve and better maintain its 280,000 buildings. Of these DoD properties, nearly 33% are more than 50 years old. As part of its strategy, the DoD is reviewing its Unified Facilities Criteria to better meet existing requirements and desired performance standards.

When upgrading, renovating and retrofitting governmental facilities, high-quality, high-performance, finished aluminum architectural products support low-maintenance, cost-effective operation. Because most government facilities serve a large number of people, the aluminum surfaces on both the high-traffic exteriors and interiors benefit from these exceptionally hard-wearing and long-lasting finishes. Building products with 70% PVDF resin-based painted coatings and Class I anodized finishes can remain in service for several decades.

Lead by Example

Improving public buildings’ energy efficiency and performance presents another critical opportunity to save operational costs, conserve resources and reduce emissions. With more than 300,000 buildings, the U.S. government is the single largest energy consumer and building manager in the nation. The Federal Sustainability Plan establishes an ambitious path to achieve net-zero emissions by 2045.

All GSA new construction and major modernization projects larger than 25,000 square feet must be net-zero emissions by 2030. Committed to these goals, the GSA requires new construction and substantial renovation of federally owned facilities to meet LEED Gold criteria at minimum. Leased buildings are required to earn an Energy Star label.

In addition to energy efficiency, government and civic projects frequently request low- and no-VOC finishes to meet sustainability goals. Single-source finishing service providers can support fenestration and framing system manufacturers with a choice of anodize and painted coatings, thermal barriers and other services to meet requirements of federal, state, local and other public facilities.

Our industry and products have key roles to play in increasing collective investment in public properties, helping deliver life-long value for current and future generations, and saving Americans billions of dollars.